The Tacoma Narrows Bridge was a modern marvel when it was first built, but soon became one of the most infamous disasters ever filmed. Before the bridge was even finished, construction workers noted how it tended to sway violently in even moderate winds, and despite efforts to make it stop, on November 7, 1940 it plummeted into Puget Sound, taking one victim with it – a dog named Tubby. Footage of the swaying bridge, which came to be known as “Galloping Gertie” has become some of the most bizarre footage ever recorded, showing a bridge made of steel and concrete twisting and flexing like it’s made of rubber. But a lot was learned from Galloping Gertie that went on to make future bridges much safer. So in today’s video, we look at this event, what led to its demise, and what we learned from it.

TRANSCRIPT:

Good morning everyone. Today let’s talk about something really sexy… Infrastructure.

Sorry, I gotta be careful so this video doesn’t get demonetized.

If you’ve been paying attention to the screaming hairdos on TV over the last year, you heard about the Infrastructure Investment and Jobs Act that was signed into law this last November. (2021)

It was contentious because… well, everything is these days, but specifically because it was a huge spending bill, it was budgeted at a trillion dollars. That’s trillion with a T. And an R. And an I. And an L. And a–

With $26.5 billion of it earmarked specifically for bridges. The Department of Transportation actually has a program for this, it’s called the Bridge Replacement, Rehabilitation, Preservation, Protection, and Construction Program. Or, the BRRPPC…P (a beat) Excuse me.

This program is the largest dedicated bridge investment since the interstate highway system was built and will help repair around 15,000 highway bridges.

But… that’s a lot of money, and it’s been a challenge to get some people behind it, so at the beginning of the year President Biden did some traveling around to some places giving speeches to promote it.

One of those places was Pittsburgh Pennsylvania, because there are a lot of bridges in that area that need repair.

So he went there on January 28th to give a speech about the need to update bridges, but he had to cancel… Because a bridge collapsed.

It was a 477-foot bridge called the Fern Hollow Bridge that was built in 1973 and had been listed in “Poor” condition by the National Bridge Registry since 2011.

here were actually 5 cars on the bridge when it went down and 10 people were injured, but thankfully nobody was killed. It really could have been a lot worse, the bridge carries 14,000 cars a day.

And the fact is there are thousands of bridges like it around the country, many of them several decades old and barely hanging on.

But at least they got several decades of good use. Unlike the first Tacoma Narrows Bridge. Which despite being a modern marvel when it was built, barely lasted 4 months.

It’s become one of the most spectacular bridge disasters of all time. A disaster that taught us a lot of lessons – that would be used to save a lot more bridges.

If you’ve never been to Seattle, you should go. It’s a lovely town and one of the reasons why it’s so lovely is Puget Sound.

Puget Sound is a complex system of channels, embayments, estuaries, and islands where the Pacific Ocean flowed in and just kinda went all crazy in there.

People wanting to travel from say, Tacoma to the Kitsap Peninsula, would have to travel far south, west, and then back north to get where they wanted to go.

Sure, ferries help transport people and are often used in the Sound. But they can be slow. And you have to follow their schedules.

Two things we Americans hate the most are a lack of freedom to hit the open road whenever we want and inefficient use of our time.

So, what do we do to guarantee those God-given rights from our Founding Fathers?

In the case of the city of Tacoma, you build a bridge. But before that, you need money, something that would prove to be a problem for the state.

The Washington State legislature created the Washington State Toll Bridge Authority in 1937 and gave $5,000 (about $97,000 today) to commission a study for a bridge over the Narrows.

An engineer named Clard Eldridge was hired and he proposed a suspension bridge design, which was still a fairly new idea, but it had worked well in other places.

They were hoping that tolls would be enough to pay for the bridge but the study showed that no, it wouldn’t be nearly enough. So, they turned to the Federal Public Works Administration (PWA).

This was the program set up by FDR to help create jobs during the Depression.

They asked for $11 million (around $220 million in today’s dollars). And many buttholes puckered.

They needed to get the cost down, so they brought in Leon Moisseiff (Mo-sieff), he was a bridge engineer from New York who was a consultant for the Golden Gate Bridge. And he had some ideas.

Early plans for the bridge included a set of 7.6-meter (25-foot) deep girders to sit under the roadway, which would make it stiff and less moveable.

He suggested using shallower 2.4-meter-deep (8 feet) supports, which meant a slimmer bridge, but also a cheaper bridge.

And like with most things in life, the PWA chose the cheaper design by Moisseiff.

It approved $6 million for the bridge. Bridge tolls would contribute almost $2 million more to help pay for it, for a total cost of $8 million.

Construction began on the Tacoma Narrows Bridge in September 1938.

It took 19 months to complete and actually came in under budget at $6.4 million.

The Tacoma Narrows Bridge had a main span of 853 meters (2,800 feet), making it the world’s third-longest suspension bridge at the time.

The Tacoma Narrows Bridge wasn’t expected to have a lot of vehicular traffic, so it was designed with just two lanes and only 12 meters (39 feet) wide.

The bridge opened on July 1, 1940.

Around 10,000 people showed up for the dedication and opening ceremony.

Tolls started at 55 cents and were reduced to 50 cents two months later after the bonds were refinanced.

Officials praised the bridge as an essential economic and military portal to the Olympic Peninsula.

It was called a triumph of man’s ingenuity and perseverance.

“Everyone marveled,” wrote historian Murray Morgan, “at the gossamer grace of a structure so long.”

But the honeymoon period ended quickly as one major problem affected the bridge, a problem that had been happening for a while.

During the final months of construction, the bridge began to move in a wave-like motion.

Workers gave it the nickname “Galloping Gertie” and would often suck on lemons to combat seasickness.

The bridge would buckle and sway during windy conditions.

Strangely, this didn’t stop people from driving across the bridge. Driving across it became like a carnival ride.

They’d wait until the wind was just “right,” and then pull their cars in line to “ride the bridge.”

Even with all the movement, people considered the bridge safe.

A bank even put up a billboard on the Tacoma side saying it was just as safe as the bridge.

Several ideas were proposed to help the bridge move less. These included

- Add cables to the girders. They were attached to 50-ton concrete blocks on the shore but broke after they were added.

- Add cable stays. These would connect the main cables to the bridge deck at mid-span. They didn’t stop the bridge from moving less.

- Add hydraulic buffers between the deck’s floor system and the towers. But this system was damaged when the bridge was sand-blasted before being painted.

The Washington Toll Bridge Authority hired engineering Professor Frederick Burt Farquharson from the University of Washington to create tests of the bridge in a wind tunnel.

The professor and his students built a 1:200-scale model of the bridge and a 1:20-scale model of a section of the deck.

He concluded his first studies on Nov. 2, 1940, offering two solutions to fix the issue.

- Create holes in the lateral girders and along the deck so air could flow through them and help reduce the lift forces.

- Add fairings or deflector vanes along the deck to give it a more aerodynamic shape.

The first option was rejected because those changes couldn’t be undone.

The second option was chosen, but it wasn’t done because there wasn’t a bridge anymore.

The Tacoma Narrows Bridge collapsed on Nov. 7, 1940, at 11 a.m., with cables snapping and concrete crashing into the water below.

Its collapse would eventually earn it the nickname “The Pearl Harbor of Engineering.”

A Tacoma reporter named Leonard Coatsworth was driving across the bridge with his dog, Tubby, on the day the bridge collapsed.

“Just as I drove past the towers, the bridge began to sway violently from side to side,” he recounted. “Before I realized it, the tilt became so violent that I lost control of the car… I jammed on the brakes and got out, only to be thrown onto my face against the curb.”

He could hear the concrete cracking. He tried to get his dog but was thrown against the curb again.

Coatsworth crawled around 457 meters (500 yards) to the towers. His hands were bleeding, bruised, and swollen. His knees were raw.

Professor Farquharson was at the bridge making measurements and ran to try and save the dog. But Tubby bit him and he gave up the effort.

Coatsworth watched from the toll plaza as the bridge broke and his car fell into the Narrows below.

Tubby was the only fatality.

So, why did the bridge collapse? Two reasons: high winds and a design that didn’t plan for them.

At that time, suspension bridges were kind of new. Most bridges were built out of concrete or stone.

Because of that, wind wasn’t much of a factor.

But with the Tacoma Narrows Bridge, there were winds of around 70 kilometers per hour on the day it collapsed.

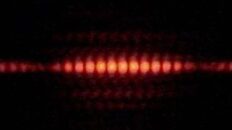

Its center torsionally vibrated at 36 cycles per minute across nine different segments.

That vibration increased, and the motion changed from rising and falling to a two-wave twisting motion.

While the center part remained pretty steady, the other two halves twisted in opposite directions.

Aeroelastic flutter caused the bridge to finally collapse.

Most bridges have trusses that let wind pass through. But with this bridge, the wind was forced to move above and below it.

This caused a flow separation. When this happens and there’s an object present, it can lead to a Kármán vortex street situation.

In the case of this situation, winds would hit the top part of the bridge, pushing it one way, while winds would hit the bottom part, pushing it the other way.

This is what caused the twisting motion and increased vibrations that led to it collapsing.

One way to help make sure this doesn’t happen is to place a gap in the middle of the bridge to allow air to flow around the structure.

Also, having trusses that allow wind to pass through is helpful.

Designers can also install diagonal braces made from steel to help make the structure stiffer when it experiences a high wind load.

The cross braces squeeze together and help prevent the bridge from flopping over.

Today, engineers and designers use model bridges in wind tunnels to test the ability of bridges to withstand high wind loads before beginning construction.

Wind loads affect all sorts of other structures besides bridges.

Skyscrapers, for example. The higher we go, the more wind forces have to be accounted for.

So engineers use computational fluid dynamic analysis and wind tunnel testing to identify pressure loads and design to counteract those forces.

They also have to design for resonance.

Much like a plucked string on a musical instrument, buildings have resonant frequencies that they are inclined to vibrate at.

Wind vortices only have an effect on a building when their frequencies line up with the building frequency.

If these vortices push back and forth at the same rate as the structure’s resonant frequency, they may create huge forces, just like what happened with the Tacoma Narrows Bridge.

But design can disrupt the wind flow around a building. Things like rough surfaces or irregular shapes help break up the wind energy into smaller energy fragments.

These fragments create smaller vortices around a structure, which leads to it being more stable.

In the end, the Tacoma Narrows Bridge was rebuilt and reopened in 1950. And you can still drive across it today.

This time, the workers nicknamed it “Sturdy Gerdie” because it was galloping no more. By the way, can everything be named by bridge workers from now on?

Suspension bridges were still new at the time but the lessons learned from this collapse have ensured that nothing like this would ever happen again.

So all we have now is this crazy footage of a bridge made of steel and concrete flapping and swaying like it’s made out of rubber. Like I’ve always been fascinated with this newsreel footage, I remember seeing it as a kid and I was just like… How?

And it was only when I researched this that I learned there was a dog in that car. RIP Tubby.

Add comment